In today’s consumer market, the demand for product quality is steadily rising.

Nowadays, when purchasing items such as clothing and footwear, consumers are no longer focused solely on style and product quality—their attention to labels and tags is also steadily increasing.

Labels Under Upgraded Quality Demands

A well-designed and finely crafted label is not only a brand identifier but also a key factor for consumers when assessing product quality. Products with strong label presence often win greater consumer favor.

This shift has brought unprecedented development opportunities to the label industry, while also placing higher demands on manufacturers.

A Dual Challenge of Craftsmanship and Production

For manufacturers, today’s market demands are becoming increasingly complex. From a craftsmanship perspective, different types of labels have unique requirements for cutting and processing.

Woven labels require precise cutting techniques to ensure clean edges and clear patterns. Printed labels demand high cutting accuracy while preserving the integrity of the printed design. Layered labels challenge the equipment’s ability to handle materials with varying thicknesses. As for printed ribbons, cutting must maintain the ribbon’s integrity while achieving diverse cutting shapes.

Traditional cutting equipment is increasingly unable to meet the dual demands of complex craftsmanship and high-efficiency production. Issues such as slow speed, low precision, and limited functionality have become bottlenecks restricting manufacturers’ growth. As a result, finding advanced equipment that can overcome these challenges has become an urgent need for many companies in the industry.

The Industrial Expert in Label Cutting

Against this backdrop, GBOS launched the X LABEL180, a high-speed laser cutting machine with vision recognition specially designed for label cutting, becoming the ideal choice for many manufacturers.

Since its market launch, it has earned a strong reputation in the label industry thanks to its outstanding performance.

In terms of speed, the X LABEL180 boasts an impressive cutting efficiency—equivalent to that of 10 XY-axis cutting machines—significantly shortening production cycles and meeting the market’s demand for fast label delivery.

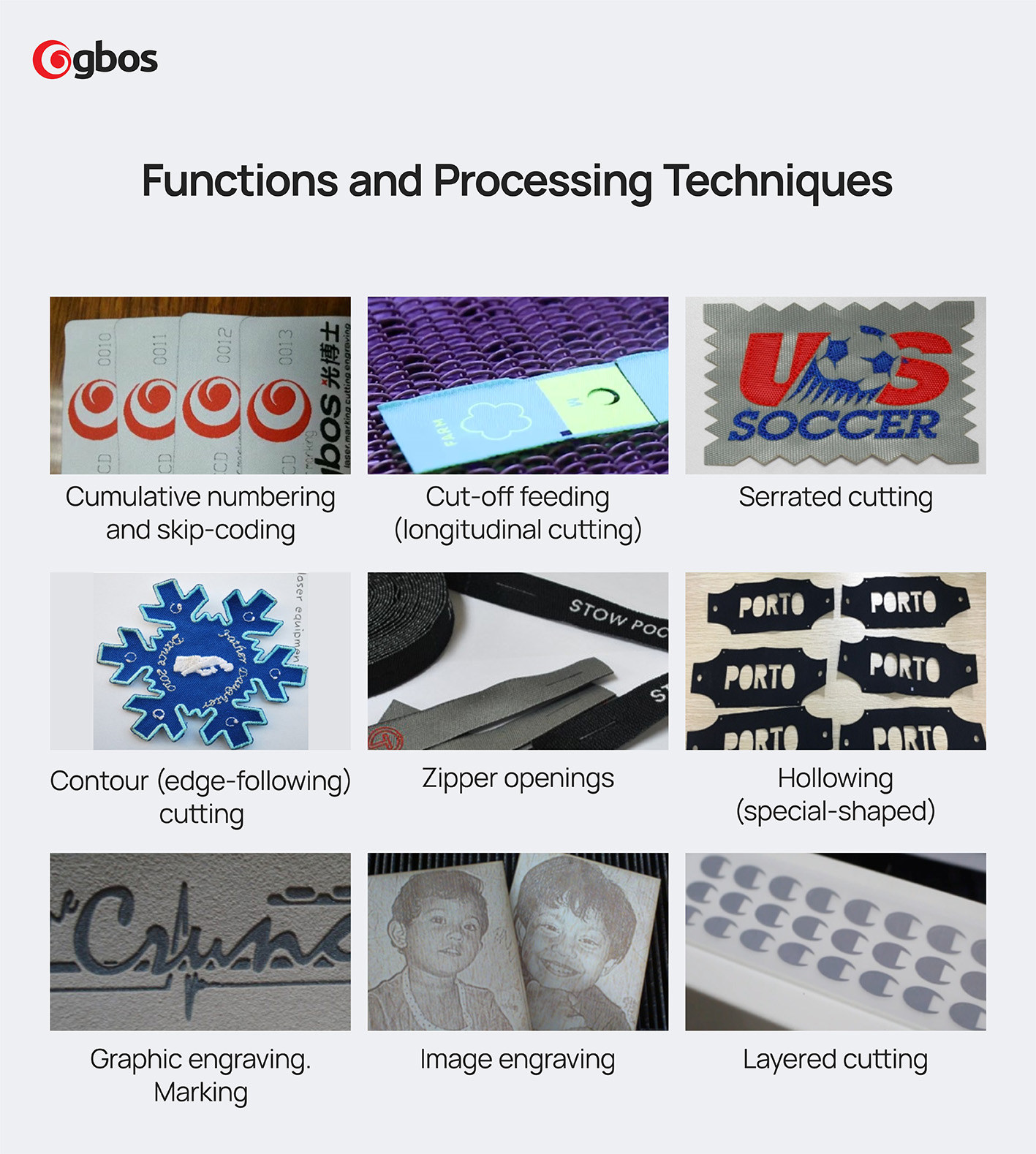

In terms of functionality and processing craftsmanship, it excels even further. Features like cumulative numbering and skip-coding facilitate easy management and traceability of labels. Cutting techniques such as cut-off feeding (longitudinal cutting), serrated cutting, and contour (edge-following) cutting enable diverse shapes to meet various label design needs. Additional functions—including zipper openings, hollowing (special-shaped), graphic engraving, marking, image engraving, and layered cutting—further expand processing possibilities, making the production of complex labels effortless and straightforward.

Additionally, the 4D smoke extraction system prevents secondary material contamination and reduces yellowing and blackening issues. The fully enclosed processing area enables contactless operation, providing a strong guarantee for safe production.

Choosing the GBOS X LABEL180 high-speed laser cutting machine with vision recognition for label cutting means choosing efficiency, precision, and quality.

It helps label manufacturers break through production bottlenecks, deliver higher-quality and more creative label products to consumers, seize the lead in fierce market competition, and usher in a new chapter in label production.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: