Recently, the topic of “PFAS in outdoor jackets affecting fertility” has sparked heated discussion, leaving many consumers deeply concerned.

PART 1. Are Outdoor Jackets Toxic? Experts Say: Don’t Panic!

According to Yang Longfeng, a science communication expert from the China Textile Engineering Society, the outer fabric of outdoor jackets often requires special coatings to achieve waterproof and breathable properties. These coatings may contain PFAS, including commonly used chemicals such as perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA), which are known to be harmful to both the environment and human health. This is one of the main reasons why the topic has triggered widespread public concern.

However, there’s no need for excessive worry. Xia Wei, Deputy Director of the Institute of Environmental Medicine at the School of Public Health, Huazhong University of Science and Technology, pointed out that claims suggesting “outdoor jackets directly cause fertility issues” are exaggerated.

Under normal usage conditions, outdoor jackets containing PFAS pose minimal direct health risks. The main concern lies in the potential for PFAS to enter the human body through hand-to-mouth contact or inhalation of dust after the coating begins to degrade or shed.

By comparison, the intake of PFAS chemicals from everyday items such as non-stick cookware may be significantly higher than that from outdoor jackets.

Experts emphasize that the primary source of PFAS exposure comes from environmental pollution during the manufacturing and disposal stages, rather than from wearing the garments themselves.

Many brands have now pledged to phase out PFAS, and consumers are encouraged to avoid purchasing clothing that contains these substances whenever possible. In China, current standards for outdoor jackets already include assessment requirements for perfluorooctane sulfonate compounds and perfluorooctanoic acid, reflecting growing efforts to ensure safer products.

In recent years, global regulations on these substances have become increasingly strict. Consumers are advised to check the garment tags when purchasing outdoor jackets to ensure the products comply with the updated standard GB/T 32614—2023 “Outdoor Sportswear — Outdoor Jackets.” This standard specifies that fluorine-free treated outer fabrics must contain less than 1.0 microgram per square meter of PFOS and PFOA.

In the future, outdoor jacket manufacturers will face higher standards for both materials and production equipment.

PART 2. Safeguarding Quality Outdoor Jackets

For garments like high-quality outdoor jackets, deep professional expertise and exquisite craftsmanship are essential. The full-material oscillating knife cutting machine VC9-1616TT serves as a reliable “sharp tool” for manufacturers.

The VC9-1616TT oscillating knife cutting machine offers manufacturers an efficient and precise solution. Utilizing automatic high-frequency vibration technology, it cuts flexible materials quickly and accurately, minimizing material waste. Without the need for cutting dies, it saves costs and time, reduces reliance on manual operation, and lowers the error rate.

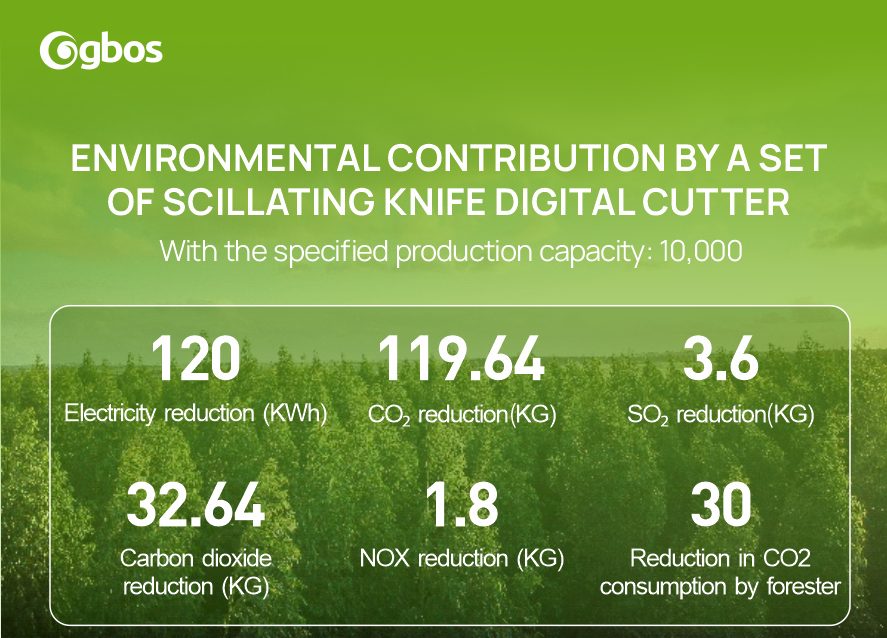

The oscillating knife cutting machine is not only an efficient and environmentally friendly cutting device but also an innovative tool driving green manufacturing. While significantly boosting productivity, it greatly reduces power consumption, helping companies achieve their energy-saving and emission-reduction goals.

In addition, the oscillating knife cutting technology can precisely cut various new high-tech fabrics, maximizing material utilization and effectively reducing resource waste. Its unique “high-frequency vibration” cutting principle completely avoids damage to material performance caused by the “thermal effect” of traditional cutting methods, ensuring every inch of material is used to its fullest and injecting new momentum into the industry’s sustainable development.

PART 3. Outdoor Jackets Offer Many Benefits — Choosing the Right One Is Key

For outdoor enthusiasts, an outdoor jacket is an essential item. Typically made with multiple layers, the inner layer is soft and comfortable, fitting closely to the body to effectively retain heat. The outer layer offers excellent waterproofing, abrasion resistance, and breathability, protecting against cold winds and rain. During activities like hiking and mountaineering, it helps keep the body warm and dry, reducing the risk of hypothermia caused by harsh weather conditions.

Outdoor jackets are equally practical in urban life. Especially during the autumn and winter seasons, when cold winds blow and rain occasionally falls, a functional outdoor jacket that meets standards allows you to easily handle various weather conditions while out and about — keeping you warm and comfortable without restricting movement.

Outdoor jackets are not “health threats.” As long as you choose products that meet standards and are of reliable quality, they can be trusted companions in daily life—shielding you from wind and rain while providing comfort. There’s no need to panic excessively about outdoor jackets; with rational choices, you can fully enjoy their benefits.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: