Range is an important indicator of the performance of new energy vehicles, and technological advances are continuously improving their range, making travelling more convenient and driving the booming development of the new energy vehicle market.

01 Batteries: the heart and soul of new energy vehicles

In the new energy vehicle family, the battery undoubtedly plays the role of the heart and soul.

It is not only the power source of new energy vehicles, but also a key factor in determining their range and environmental performance. A high-quality battery means longer range, fewer recharges, and lower energy consumption and emissions. Therefore, a good or bad battery directly determines the market competitiveness of new energy vehicles.

In the market, although the positioning of the car is not entirely determined by the battery, the performance of the battery has undoubtedly become one of the important factors affecting the positioning of the car. Whether it is a luxury model that pursues extreme range or a low-end model that focuses on economy and practicality, a battery with excellent performance is indispensable.

02 Dilemmas and challenges of traditional wire stripping methods

However, in the production process of new energy vehicle batteries, the stripping of copper flexible connecting wires faces many difficulties and challenges. Traditional stripping methods, such as mechanical cutting or manual stripping, are not only inefficient, but also prone to cause damage to the wire.

What’s more, these traditional methods rely heavily on workers’ skills and emotions, making it difficult to stabilise product quality. Once workers operate improperly or have mood swings, it is easy to cause product quality problems and bring unnecessary losses to the enterprise. In addition, traditional methods of wire stripping also have the problems of high energy consumption and consumables, which further increase the production cost and environmental burden of enterprises.

03 Laser Stripping: A Revolutionary Approach to New Energy Vehicle Batteries

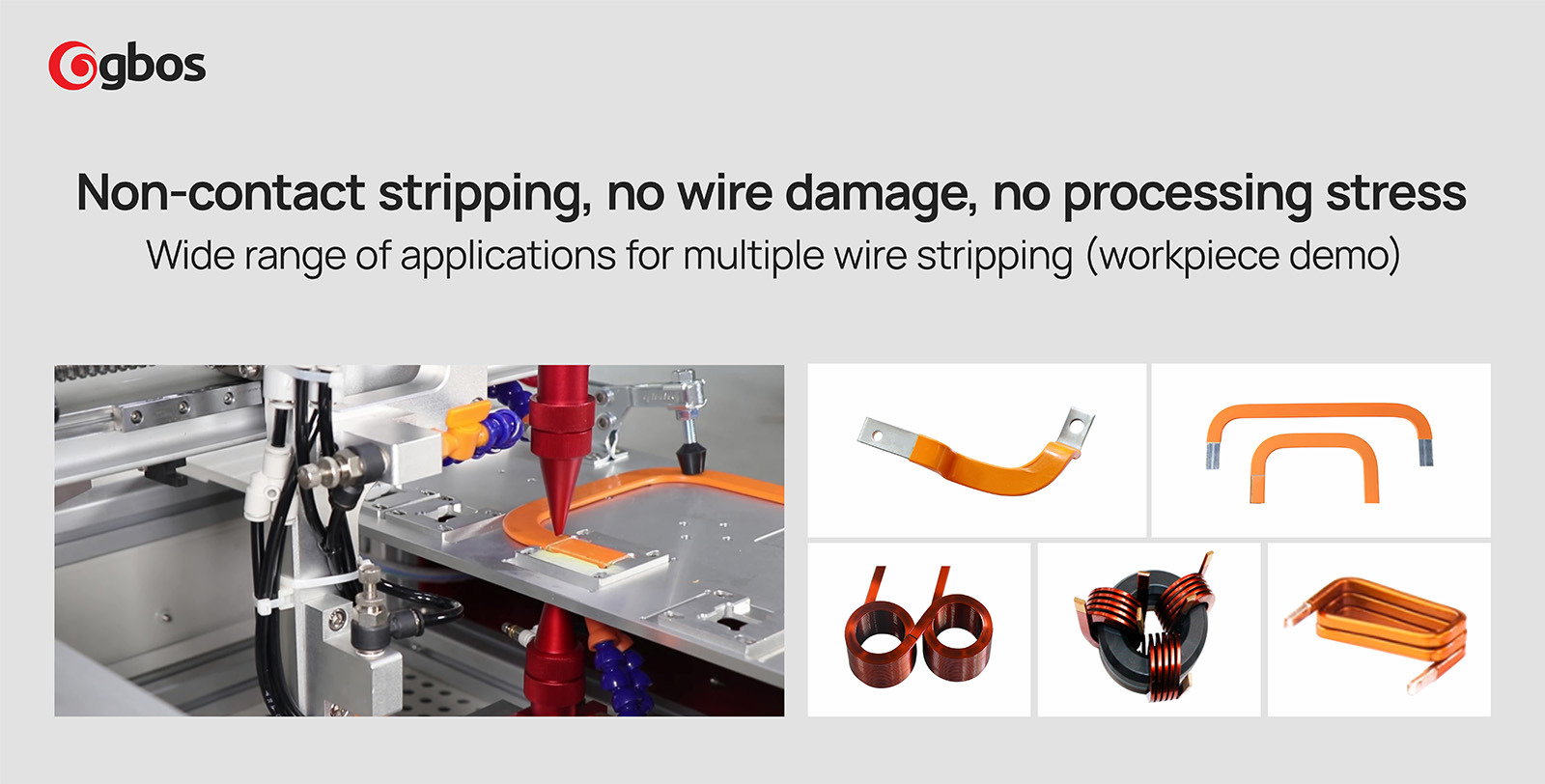

In order to solve the drawbacks of traditional wire stripping methods, laser wire stripping technology came into being – GN210-BX-FB high-efficiency precision laser wire stripping machine.

- As a highly efficient and precise method of wire stripping, laser stripping enables a contactless process with the wire, avoiding the processing stresses and wire damage caused by contact in the traditional way.

- At the same time, laser stripping is independent of workers’ skills and emotions, ensuring stable and consistent product quality.

- Laser wire stripping it is not only able to accurately control the depth and width of the stripped wire, does not damage the metal layer, does not affect the performance of the product; it also supports segmental stripping or medium stripping, which meets the needs of different users.

- In addition, laser wire stripping also has the advantages of energy saving and environmental protection, no consumables, greatly reducing the production cost and environmental burden of enterprises.

We believe that in the near future, new energy vehicles will become the first choice for people’s travelling with its more excellent performance and environmental protection advantages; and the laser wire stripping technology will also become an indispensable part of the production process of new energy vehicle batteries, contributing to the sustainable development of the new energy vehicle industry.

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: