-

AI-Driven, smart footwear Manufacturing 4.0: zero cutting-dies, one-stop digital cutting solutions.More Details

AI-Driven, smart footwear Manufacturing 4.0: zero cutting-dies, one-stop digital cutting solutions.More Details -

Comprehensive Digital Cutting Solutions: Precision in Every Layer. Incorporating innovative process solutions, leading the digital transformation in fabrication, offering impeccable cutting solutions from single to multi-layers.More Details

Comprehensive Digital Cutting Solutions: Precision in Every Layer. Incorporating innovative process solutions, leading the digital transformation in fabrication, offering impeccable cutting solutions from single to multi-layers.More Details -

The camera quickly captures the outline of the label for precise cutting. The software automatically identifies unqualified products and cuts without burnt edges or yellow edges. Any angle of label is possible.More Details

The camera quickly captures the outline of the label for precise cutting. The software automatically identifies unqualified products and cuts without burnt edges or yellow edges. Any angle of label is possible.More Details -

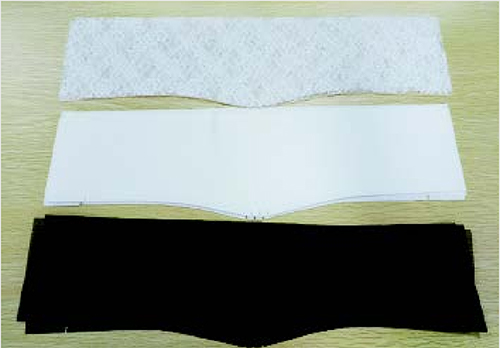

AI VisionScan tech elevates lace cutting precision. Combined with our VisionScan PUR dispensing system and 3D non-contact bra cup cutting, we provide a streamlined digital solution for lingerie production, maximizing material use and ROI.More Details

AI VisionScan tech elevates lace cutting precision. Combined with our VisionScan PUR dispensing system and 3D non-contact bra cup cutting, we provide a streamlined digital solution for lingerie production, maximizing material use and ROI.More Details -

Used for trimming and cutting of irregular-shaped materials, this machine replaces traditional CNC machining methods and improves efficiency by over 3 times while reducing investment in molds and accelerating the development cycle of new products.More Details

Used for trimming and cutting of irregular-shaped materials, this machine replaces traditional CNC machining methods and improves efficiency by over 3 times while reducing investment in molds and accelerating the development cycle of new products.More Details -

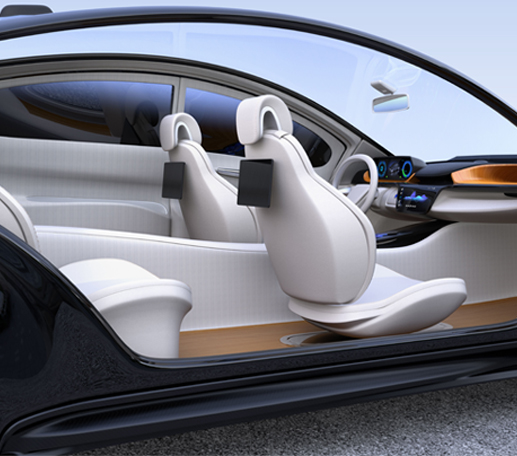

Laser cutting seat cover, and other automotive interior materials becomes a trend due to the versatile laser technics of laser cutting, laser perforating, laser marking, and laser engraving.More Details

Laser cutting seat cover, and other automotive interior materials becomes a trend due to the versatile laser technics of laser cutting, laser perforating, laser marking, and laser engraving.More Details -

Green solutions with less water, less chemical, less energy, less emission, one standard for production, and easy operation.More Details

Green solutions with less water, less chemical, less energy, less emission, one standard for production, and easy operation.More Details -

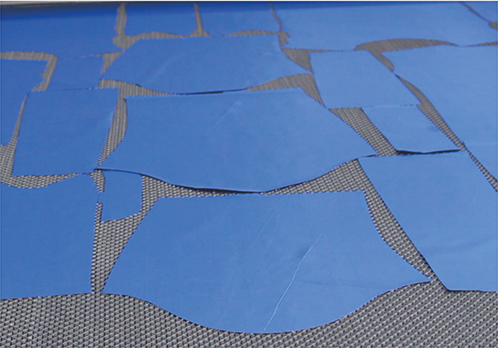

In the traditional leather cutting filed, it faced many problem! How to solve it?More Details

In the traditional leather cutting filed, it faced many problem! How to solve it?More Details -

One-stop solutions for greeting card industry. (Laser Marking/Engraving/Cutting All in One)More Details

One-stop solutions for greeting card industry. (Laser Marking/Engraving/Cutting All in One)More Details -

Customers pay more attention to personalized requirements and one machine with multiple functions.More Details

Customers pay more attention to personalized requirements and one machine with multiple functions.More Details -

GBOS's intelligent automated nesting combined with expert upholstery cutting and marking solutions, ensure optimal cost control without compromising quality.More Details

GBOS's intelligent automated nesting combined with expert upholstery cutting and marking solutions, ensure optimal cost control without compromising quality.More Details

Stock Code: 870145

Industry Solutions

Book an virtual demonstration with us to learn more about digital cutting and process solutions.

Request A Web/On Site Demo

Get Manufacturing and Process Solutions

Conatct now

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China

Address: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District,Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  Email:

Email: