Era baru manufaktur cerdas telah tiba. Apakah Anda siap untuk tahun 2021 mendatang? Beri diri Anda kesempatan untuk menguasai pasar terlebih dahulu dan ciptakan bengkel produksi digital yang mengintegrasikan kecerdasan, otomatisasi, dan informatisasi.

SIARAN LANGSUNG DI FACEBOOK!

Waktu: 18 Desember 2020 10:10, GMT +0800

Bertujuan untuk "Lebih dari sekadar cepat, lebih cepat dari cepat, menerobos mil terakhir dari pemotongan cerdas," Mari jelajahi solusi pemotongan, penandaan garis, pelubangan, dan semprotan lem bersama-sama! Dan jelajahi aplikasi pemotongan bersama-sama!

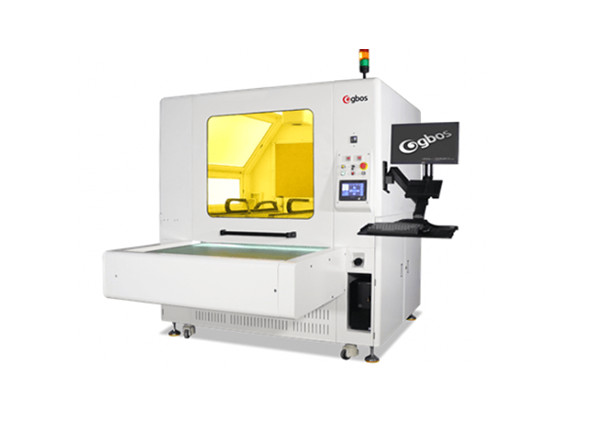

Tampilkan peralatan

- VC9-1670TPemotong pisau berosilasi, ketebalan pemotongan maksimal: 18mm.

- GC850SCCD-P-EPMesin untuk penggunaan di seluruh adegan, penggunaan material penuh! Terobosan pada mil terakhir dari pemotongan cerdas.

- XXP3.2-180-CCDMesin penandaan laser berkecepatan tinggi.

- V10SCCD, SCCD untuk mengekstraksi kontur dan memotong bagian atas sepatu cetak digital.

- R3, sistem lem Smart Spray untuk sepatu.

- LA-GN1280TT-SCCD-AT, Mesin garis penandaan otomatis pintar asinkronisasi kepala ganda 5G.

- ITS2Sistem sarang yang cerdas.

- VC9-1612Pesanan kecil, model sampel.

Memberi Anda satu set solusi otomatis, dan membantu pabrik sepatu Anda memasuki Industri 4.0 sebelum tahun 2021! Membantu Anda memasuki pemotongan tanpa cetakan yang cerdas; Memasukkan pola, memotong, memberi makan, mengumpulkan, menghitung semua dalam satu; Disesuaikan dan banyak lagi!

Alamat #B1, 8 Bagian DongCheng, Jalan Danau Songshan, Distrik DongCheng, Dongguan, Guangdong, Tiongkok

Alamat #B1, 8 Bagian DongCheng, Jalan Danau Songshan, Distrik DongCheng, Dongguan, Guangdong, Tiongkok  Tel: +86 769 88990609

Tel: +86 769 88990609  Faksimili: +86 769 88990677

Faksimili: +86 769 88990677  Email:

Email: