Durante quatro dias inteiros, os clientes ficam apaixonados o tempo todo!

Máquinas nessa exposição de calçados (19/04 a 22/04)):

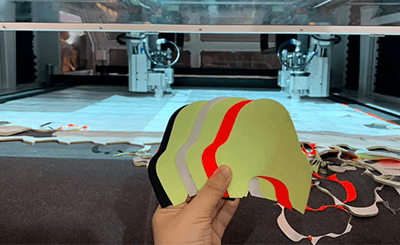

1. VC9-1670, Máquina de corte+perfuração com faca digital assíncrona de dois cabeçotes para materiais de acessórios de calçados.

Aqui, o corte com faca digital TPU de 6 camadas.

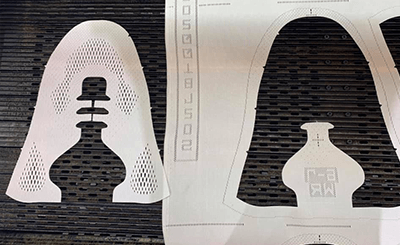

2. V10-SCCDCorte a laser da parte superior da malha VisionScan.

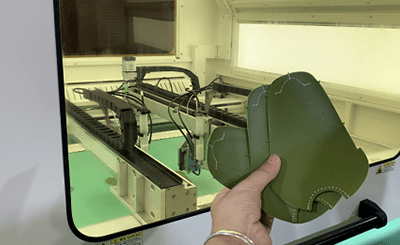

3. LA-GN1280TT-AT-SCCDMáquina de marcação de linha automática de alta velocidade com dois cabeçotes.

4. XXP3.2-180CCDO processo de posicionamento de furos com marcação a laser.

E uma máquina nova e pronta para a exposição!

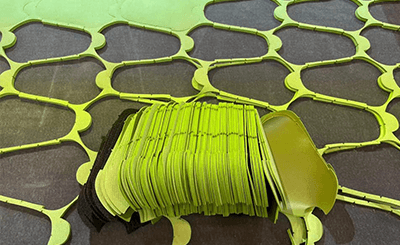

VC9-1616, materiais de acessórios completos para calçados, corte digital com faca.

Entre eles, VC9-1670, LA-GN1280TT-AT-SCCD, VC9-1616 foram vendidos nessa exposição! Obrigado por seu apoio, esta é uma exposição de sucesso!

Esperamos encontrá-lo em breve na 30ª Exposição Internacional de Calçados de Guangzhou, de 31 de maio a 3 de junho.

Endereço: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District, Dongguan, Guangdong, China

Endereço: #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District, Dongguan, Guangdong, China  Tel: +86 769 88990609

Tel: +86 769 88990609  Fax: +86 769 88990677

Fax: +86 769 88990677  E-mail:

E-mail: