4일 내내 고객들의 열정이 가득합니다!

이번 신발 전시회(04.19-04.22) 참가 기계(04.19-04.22):

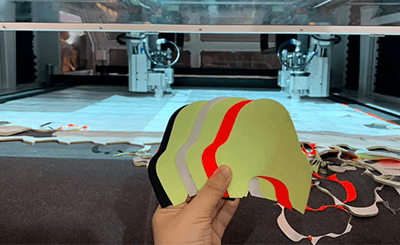

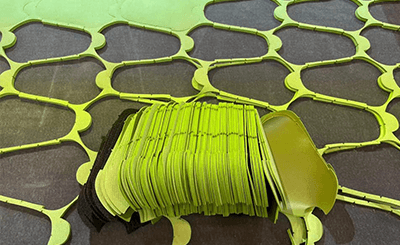

1. VC9-1670, 신발 액세서리 재료용 더블 헤드 비동기 디지털 나이프 커팅+펀칭기.

여기, 6층 TPU 디지털 나이프 커팅.

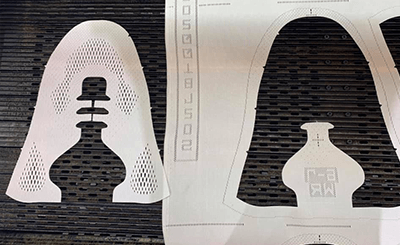

2. V10-SCCD, 비전스캔 메쉬 상부 레이저 커팅.

3. LA-GN1280TT-AT-SCCD, 더블 헤드 고속 자동 라인 마킹 기계.

4. XXP3.2-180CCD레이저 마킹으로 구멍 프로세스를 배치합니다.

그리고 이번 전시회에는 새로운 기계가 등장합니다!

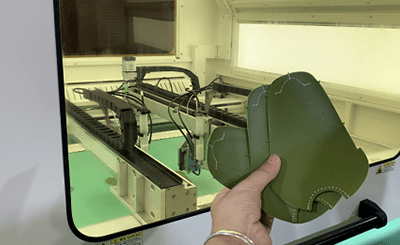

VC9-1616, 전체 신발 액세서리 재료 디지털 나이프 절단.

이 중 VC9-1670, LA-GN1280TT-AT-SCCD, VC9-1616 이 전시회에서 판매되었습니다! 여러분의 성원에 힘입어 성공적인 전시회를 마쳤습니다!

곧 5월 31일부터 6월 3일까지 열리는 제30회 광저우 국제 신발 전시회에서 여러분을 만나 뵙기를 기대합니다.

주소: 중국 광둥성 둥관시 둥청구 송산 호수 애비뉴 둥청 섹션 #B1, 8 둥청 섹션, 송산 호수 애비뉴, 중국 광둥성 둥관시 둥청구, 8 둥청 섹션

주소: 중국 광둥성 둥관시 둥청구 송산 호수 애비뉴 둥청 섹션 #B1, 8 둥청 섹션, 송산 호수 애비뉴, 중국 광둥성 둥관시 둥청구, 8 둥청 섹션  전화: +86 769 88990609

전화: +86 769 88990609  팩스: +86 769 88990677

팩스: +86 769 88990677  이메일:

이메일: