GBOS laser Inc (abréviation de l'action : GBOS, code de l'action : 870145) et détenu

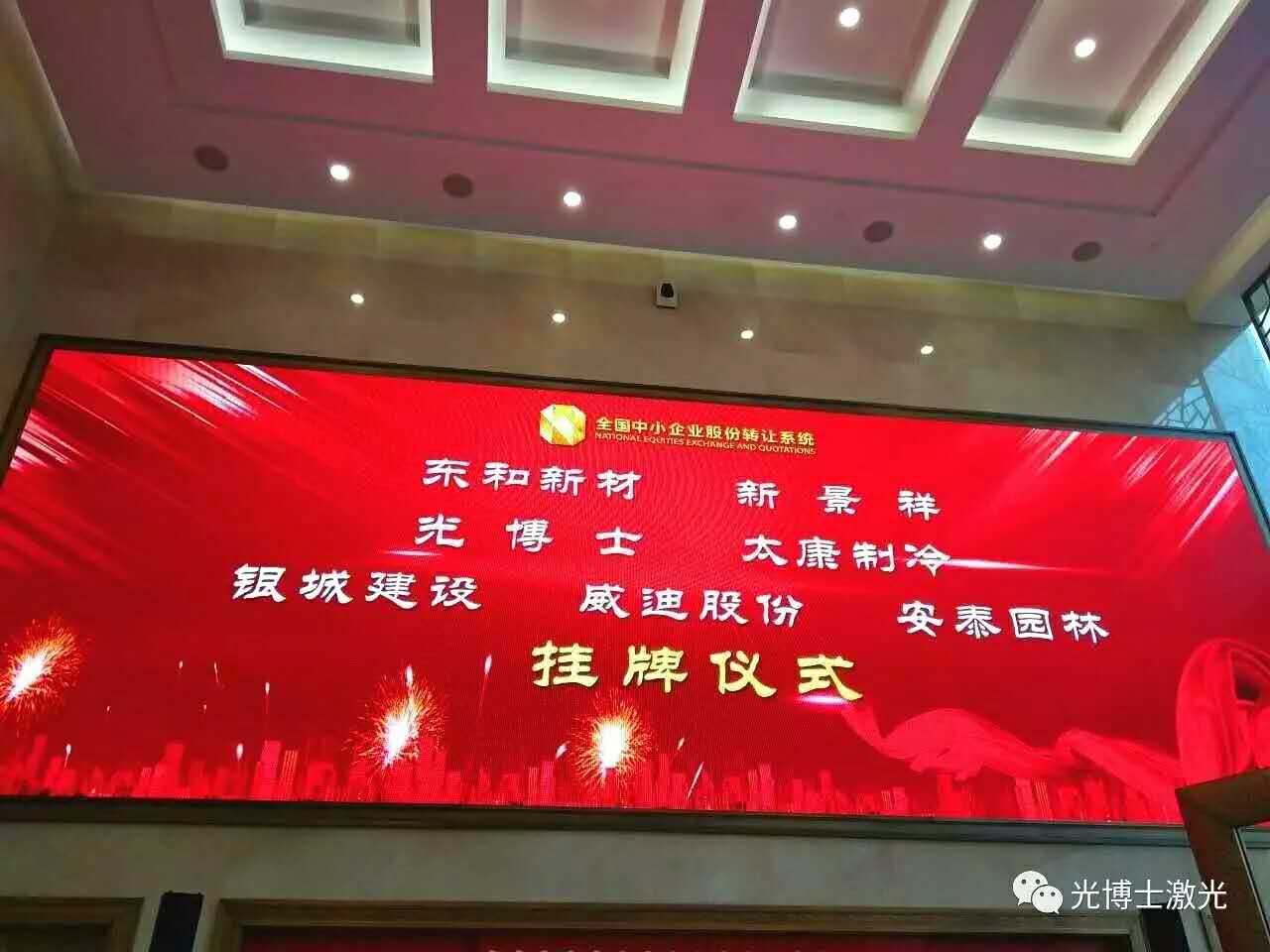

Le 27 février, deuxième jour du deuxième mois du calendrier lunaire chinois, connu sous le nom de "tête de dragon", la principale marque nationale de lumière laser intelligente de la ville de Dongguan, le laser Polytron, a été inaugurée.

Le président Liu Wu, le directeur de la société GBOS Laser Technology, le directeur des ventes et le directeur administratif ont assisté conjointement à la cérémonie d'introduction en bourse, moment important de l'histoire de la société GBOS Laser.

Lors de la cérémonie de cotation, le président Liu a prononcé un discours en tant que représentant d'une entreprise collective cotée en bourse. Il a déclaré : "J'espère que le laser GBOS avec trois nouveaux conseils d'administration sera un nouveau point de départ, une nouvelle opportunité, qu'il fera bon usage du nouveau conseil d'administration de la plateforme pour remplir les obligations de divulgation d'informations, renforcer la gestion scientifique, établir une bonne image de marque de l'entreprise, avec d'excellentes performances en matière de rendement social, de rendement pour les actionnaires et les investisseurs.

La direction de l'entreprise photo de cloche

Merci encore, laser GBOS pour les collègues qui se battent,

Parce que vous tous !

Adresse : #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District, Dongguan, Guangdong, Chine

Adresse : #B1, 8 DongCheng Section, Songshan Lake Avenue, DongCheng District, Dongguan, Guangdong, Chine  Tel : +86 769 88990609

Tel : +86 769 88990609  Fax : +86 769 88990677

Fax : +86 769 88990677  Courriel :

Courriel :