모든 위대한 여성들에게 행복한 여성의 날을 축하합니다. 물론 오늘뿐만 아니라 매일매일 말이죠.

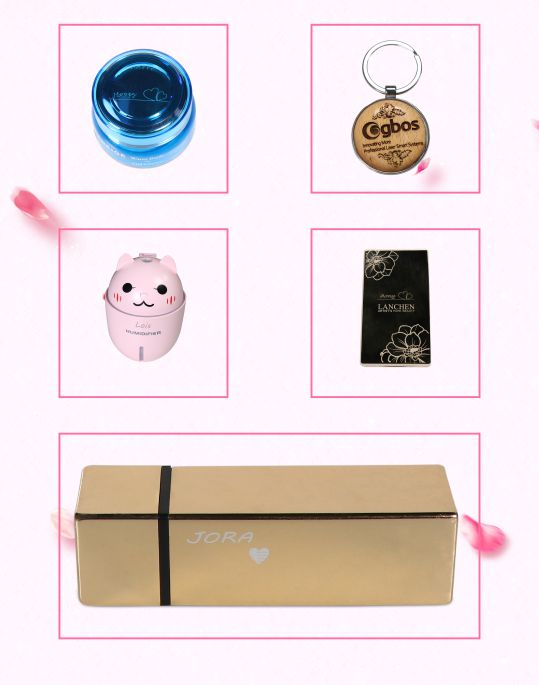

인생은 항상 선택을 요구하고, 여자 친구를위한 립스틱을 DIY 한 다음 그녀를 위해 자신의 로고를 표시하는 레이저 조각기 기계를 사용하십시오! 그런 우리 : 그녀의 이름, 그녀의 생일, 당신의 기념일 등, 그것은 놀라운 선물이어야하며 가장 다채로운 대답이 될 것입니다!

금속, 플라스틱, 가죽 케이스 모두 가능합니다. 원하는 문구와 패턴을 레이저로 각인할 수 있습니다!

금속, 플라스틱, 가죽 케이스 모두 가능합니다. 원하는 문구와 패턴을 레이저로 각인할 수 있습니다!

그녀만을 위한 립스틱을 커스터마이징하세요! 다른 선물도 레이저 기계로 각인할 수 있습니다.

주소: 중국 광둥성 둥관시 둥청구 송산 호수 애비뉴 둥청 섹션 #B1, 8 둥청 섹션, 송산 호수 애비뉴, 중국 광둥성 둥관시 둥청구, 8 둥청 섹션

주소: 중국 광둥성 둥관시 둥청구 송산 호수 애비뉴 둥청 섹션 #B1, 8 둥청 섹션, 송산 호수 애비뉴, 중국 광둥성 둥관시 둥청구, 8 둥청 섹션  전화: +86 769 88990609

전화: +86 769 88990609  팩스: +86 769 88990677

팩스: +86 769 88990677  이메일:

이메일: